In the competition for the construction of the new campus of Huzhou University, a large-scale ceramic anti-static flooring project posed a "triple dilemma" for all suppliers: customized ceramic patterns, load-bearing requirements far exceeding national standards (point load 420 kg, uniformly distributed load 23,000 N), and strict budget control. What seemed like an impossible task was ultimately accomplished by Jiangsu Zhongtian Anti-Static Flooring Co., Ltd., under the leadership of Zhuang Meiquan, who cracked the problem with precise technology and earned trust through collaboration, securing all three bidding sections.

At the beginning of the project, conventional solutions encountered challenges. Customized patterns meant special production lines and higher costs, while extremely high load-bearing requirements usually required thicker steel plates and reinforced structures, inevitably causing costs to soar far beyond the client’s budget. Facing this dilemma, Zhuang Meiquan did not simply give up or compromise on quality. She personally led the team to conduct multiple rounds of in-depth technical coordination with the Huzhou Huayu Group project team. She proposed a core idea: "Not to make the most expensive, but to make the most appropriate."

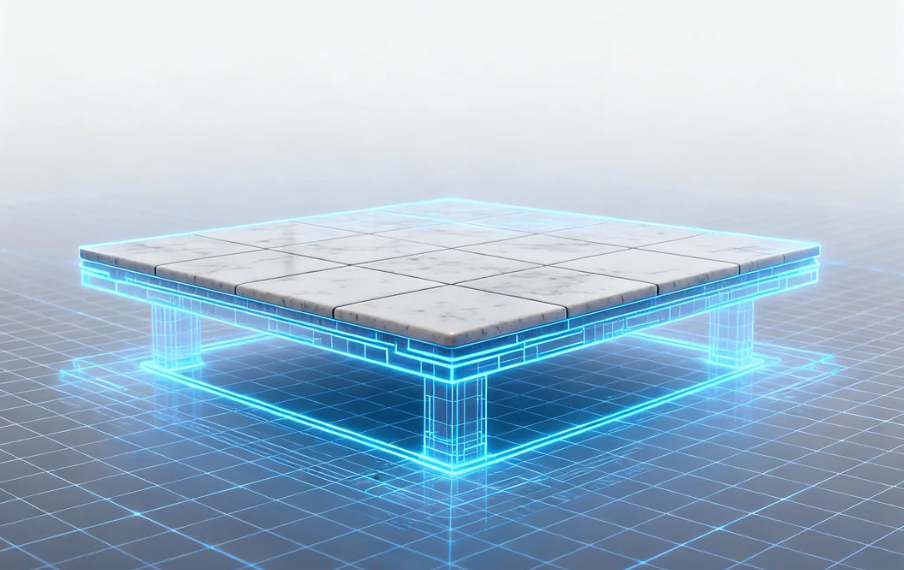

Following this idea, Zhuang Meiquan’s team quickly shifted to tackling "structural optimization" and "cost-performance selection". They abandoned the conventional method of material stacking and, through precise calculations, implemented revolutionary adjustments and reinforcement designs to the internal structure of the flooring system and the support keel distribution plan. This ensured that both point load and uniformly distributed load standards were met, while cleverly selecting the most cost-effective material combination. At the same time, she actively coordinated with ceramic surface suppliers, optimizing procurement and production processes to control the cost of customized patterns within a reasonable range.

Ultimately, a customized elevated movable flooring solution with excellent mechanical performance and cost advantages was developed, with the unit price successfully controlled within the target of 200 yuan per square meter. This solution not only fully met the functional requirements of the school but also showcased Jiangsu Zhongtian’s profound technical expertise and cost-control capabilities. Huzhou Huayu Group gave high praise to the final results during the solution review and subsequent commissioning.

Thanks to this highly competitive solution and the professional collaborative spirit demonstrated by Zhuang Meiquan’s team, Jiangsu Zhongtian won the client’s absolute trust, successfully completing the supply and construction of the three bidding sections in stages. This project not only became a model of school-enterprise cooperation but also highlighted Jiangsu Zhongtian’s strong comprehensive strength in facing complex demands by using technology as a spear and collaboration as a shield.